Vibrating Table, a versatile and efficient tool designed for various applications, including material compaction, settling, and testing. Whether in construction, manufacturing, or research and development, our Vibrating Table provides a reliable solution for achieving optimal material density and uniformity. Here are the key features that make our Vibrating Table stand out:

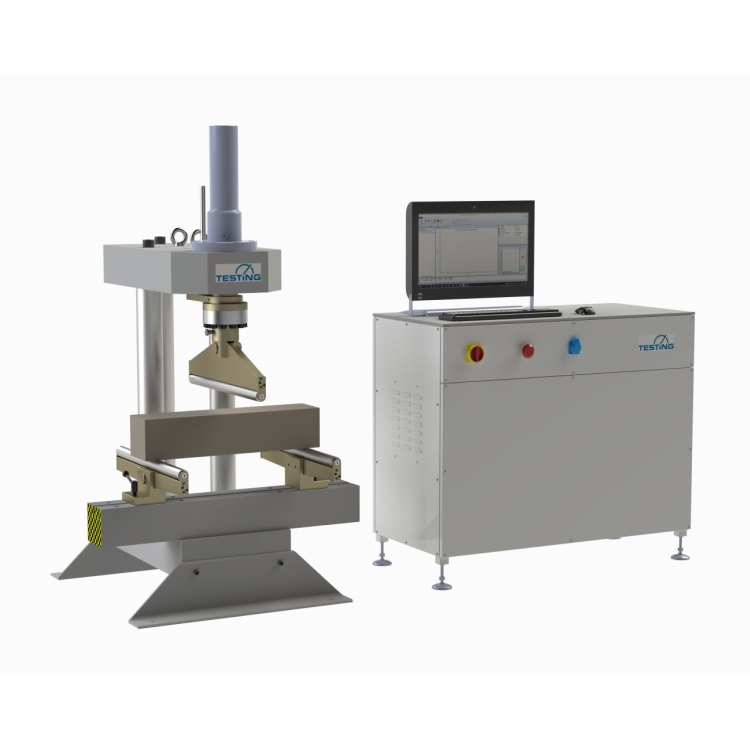

Testing

Vibrating Table

Key Features:

- Efficient Material Compaction: Our Vibrating Table is engineered for effective compaction of a variety of materials, such as concrete, plaster, and granular substances. This ensures enhanced material density and reduces the risk of voids or air pockets.

- Variable Vibration Settings: The table offers adjustable vibration settings, allowing users to customize the intensity and frequency of vibrations based on the specific requirements of the material being processed.

- Sturdy Construction: Built with durability in mind, our Vibrating Table features a robust frame and vibration mechanism, ensuring stability and reliability during the compaction process.

- Versatile Table Sizes: The Vibrating Table is available in various sizes to accommodate different material quantities and sizes. This versatility makes it suitable for a range of applications, from small-scale testing to large-scale production.

- Easy-to-Operate Controls: The user-friendly controls make it easy to operate the Vibrating Table. Intuitive settings and a clear interface enhance the efficiency of the compaction process.

- Portable Design: Despite its robust construction, the Vibrating Table is designed for portability, allowing for easy movement and deployment in different work environments.

- Material Compatibility: Our Vibrating Table is compatible with a wide range of materials, making it a versatile tool for various industries, including construction, foundry, and material testing.

- Quality Assurance: The Vibrating Table assists in achieving consistent and uniform material compaction, contributing to quality assurance in manufacturing processes and construction projects.

- Reduced Air Voids: By efficiently compacting materials, the Vibrating Table minimizes the presence of air voids in the final product, resulting in improved strength and durability.

- Customizable Configurations: Depending on the application, our Vibrating Table can be configured with additional features or accessories to meet specific user requirements, providing a tailored solution for various industries.